High Density Chemical Imaging System

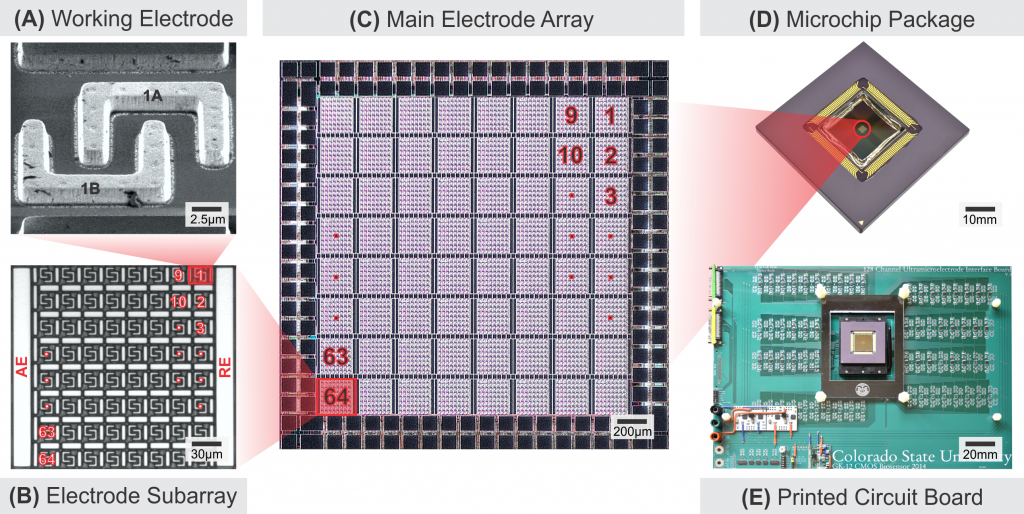

The use of modern semiconductor manufacturing processes allows integration of electrodes and electronics into a single device. Integrating electrodes and electronics allows exponential increases in the number of channels (or pixels) that can be analyzed simultaneously while also providing significant reductions in parasitic resistance & capacitance and thereby associated noise levels yielding more sensitive measurements.

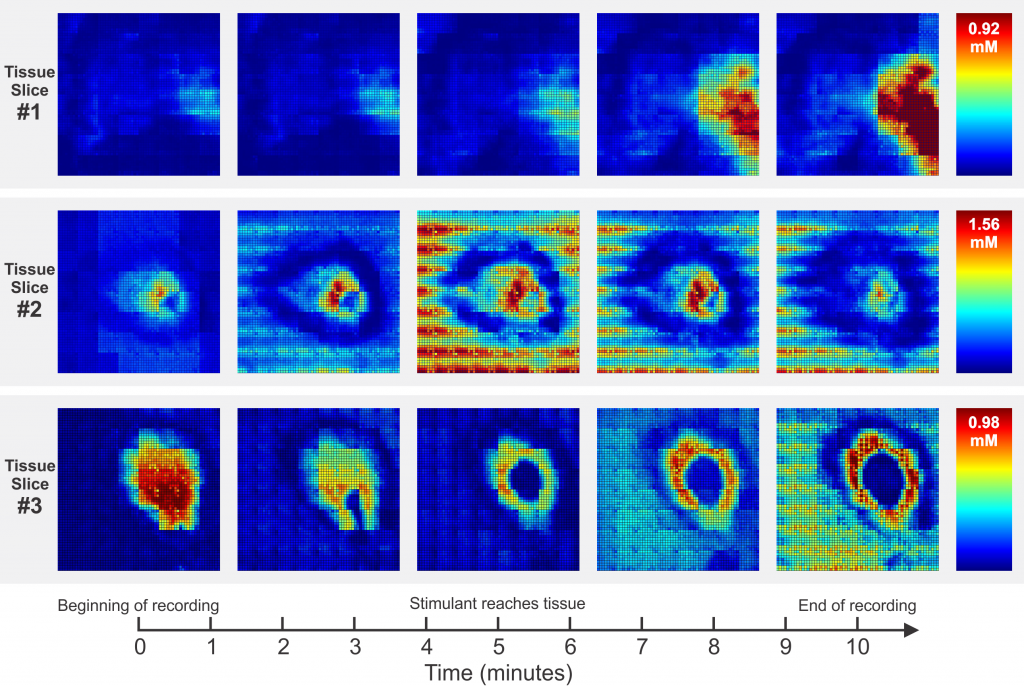

Our integrated approach provides the ability to electrochemically image concentration gradients of target analytes in real time across long distances and functional tissue slices while simultaneously tracking important biological functions like cell migration, thereby addressing the need for chemistry specific imaging across multiple length scales. In addition to using the chemical imaging system to understand cell migration and cell-cell communication, the technology can also be used to determine efficacy of drugs by monitoring the health of tissue slice while different drugs are applied. Doctors could personalize their treatment for specific patient.

1st Generation System

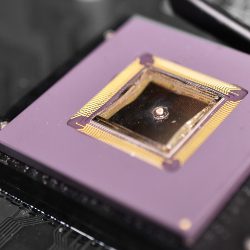

1st generation chemical imaging system contains 8,192 electrodes in a 2mm X 2mm grid and integrates the on-chip potentiostat. The electrodes can be used either as a group of 64 electrodes (subarray) for higher sensitivity and temporal resolution or addressed through 64 subarrays to gain larger coverage area with lower temporal resolution.

Chemical Imaging System

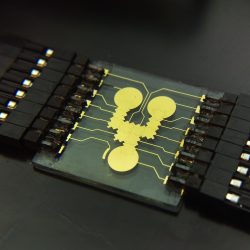

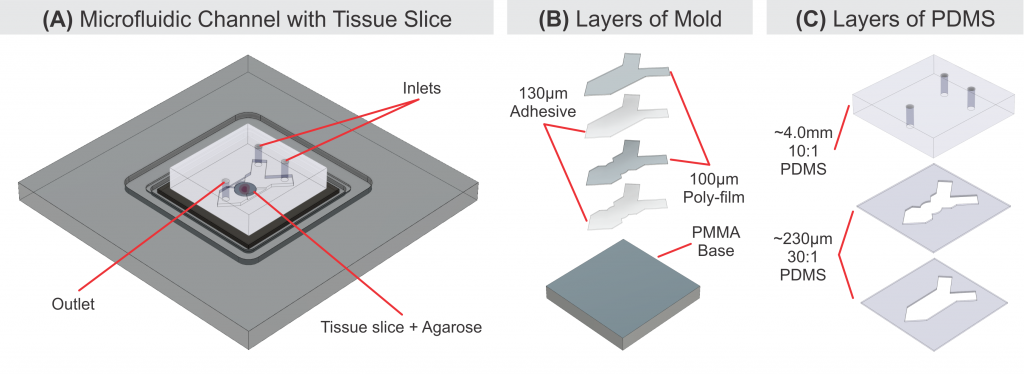

Microfluidics Design and Fabrication

Chemical Imaging Heatmaps of Stimulated Murine Adrenal Gland

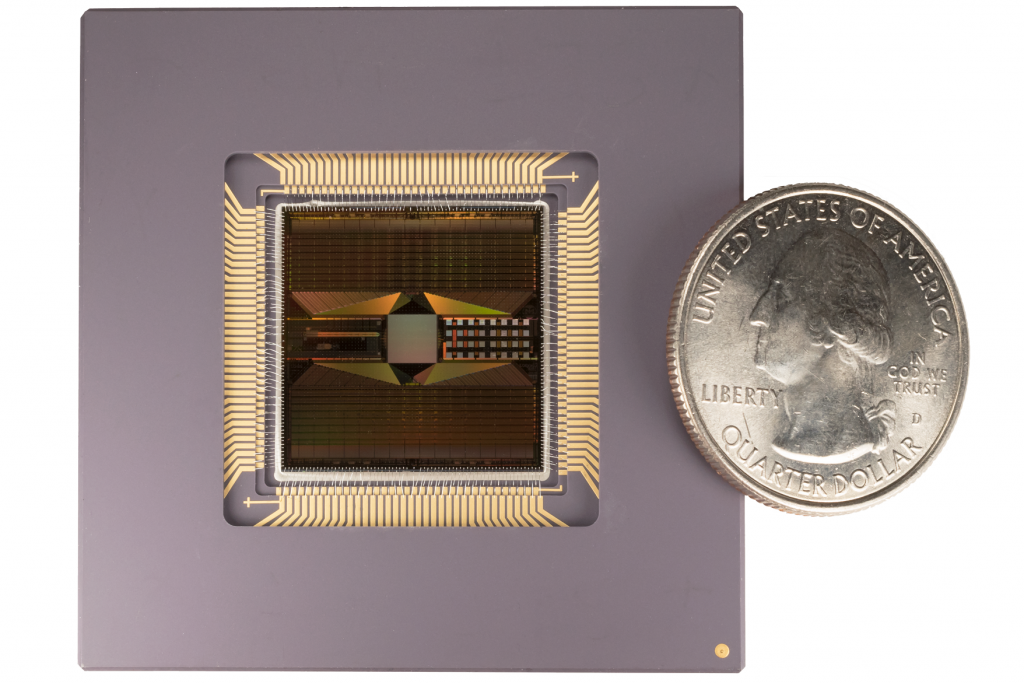

2nd Generation System

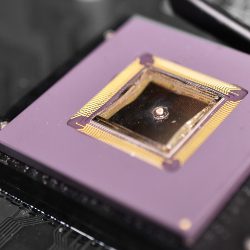

The 2nd generation CMOS-based microchip with Pt electrodes was designed and fabricated using the same technology node as the 1st generation. It employs 16,000 sensing electrodes covering 3.6mm X 3.6mm area with their own one-to-one individual read channels. The system is expected to sense and generate chemical heatmap movies with 16,000 pixels in real-time. The photograph below shows the 2nd generation CMOS-based microchip with 16,000 electrodes.

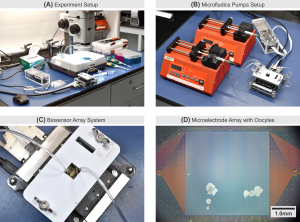

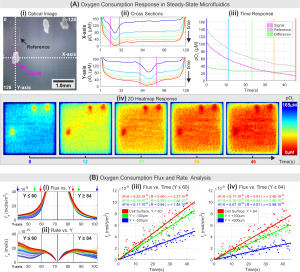

One of the applications of the 2nd generation integrated microelectrode array for chemical imaging is real-time measurement of oxygen consumption rate (OCR) of live cells to provide two-dimensional (2D) oxygen concentration gradient images. The diagram below shows an in-vitro oxygen imaging experiment setup to analyze bovine cumulus-oocytes-complexes cells OCR and oxygen flux density. The integration of a microfluidic system allows proper bio-sample handling and delivery to the MEA surface for imaging.

The results presented as two-dimensional (2D) heatmaps, representing the dissolved oxygen concentration in the immediate proximity of the MEA show that the imaging capability of the MEA system to allow users to observe spatial and temporal dynamics of target cell metabolism.

Walter Scott, Jr. College of Engineering

www.engr.colostate.edu

700 Meridian Ave

1301 Campus Delivery

Fort Collins, CO 80523-1301

(970) 491-3366

School of Biomedical Engineering

www.engr.colostate.edu/sbme

700 Meridian Ave

1376 Campus Delivery

Fort Collins, CO 80523-1376

(970) 491-7157

Walter Scott, Jr. College of Engineering

www.engr.colostate.edu

700 Meridian Ave

1301 Campus Delivery

Fort Collins, CO 80523-1301

(970) 491-3366

School of Biomedical Engineering

www.engr.colostate.edu/sbme

700 Meridian Ave

1376 Campus Delivery

Fort Collins, CO 80523-1376

(970) 491-7157